How to solve Supply Chain recurring problems with known symptoms

The Supply Chain is subjected to face strong constraints, because of the flows growing complexity:

- Shorter product life cycle

- More pressure on deadlines and diversity in demand

- Larger networks of actors covering wider geographical areas

There’s an immediate impact on :

- Stock out

- Delays

- Changing and contradictory decisions

One solution exists: Demand Driven Material Requirements Planning (DDMRP)

DDMRP is a multi-level monitoring method, pull-flow planning and implementation aimed to protect and promote flows.

It enables the optimization of inventory levels to best satisfy market demand, by relying on stock buffers at strategic points in the BOMs through the distribution network.

DDMRP relies on firm demand rather than forecasts to generate and manage replenishment orders, whether for manufacturing, transfers or external purchases.

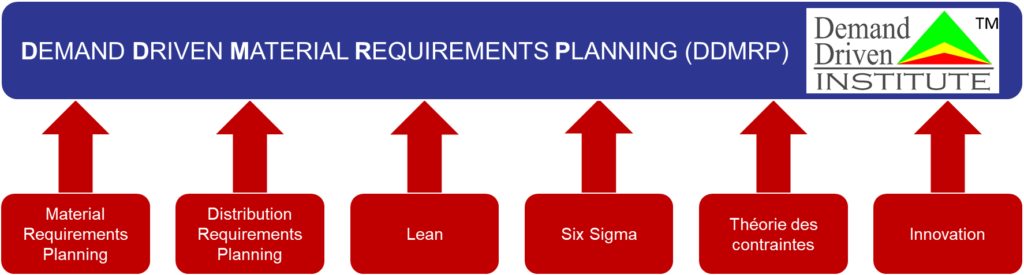

A Smart Combination

The method adds its innovations on recognized concepts elements :

- Material Requirements Planning (MRP)

- Distribution Requirements Planning (DRP)

- Lean Manufacturing

- Theory of Constraints

- Six Sigma

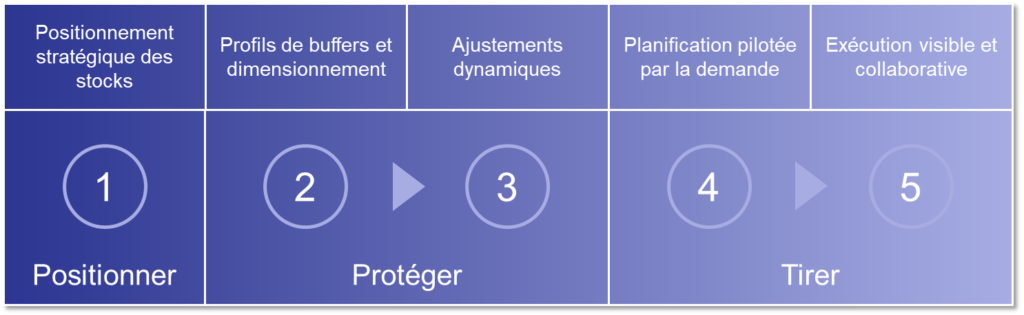

The 5 components of the DDMRP

Here are the 5 steps of a DDMRP implementation :

1.Position strategic decoupling points

2. Sizing the buffers

3. Dynamically adjust buffers

4. Planning by actual demand

5. Execute planned orders collaboratively and visually

Convincing results

The first results of the DDMRP show a refocusing of stock levels closed to optimal levels :

The smart management of these inventory levels induces important benefits on the whole Supply Chain, translated by an improvement of the key indicators (source: Demand Driven Institute):

Improvement of the service rate

97% – 100%

Time compression

80%

Inventory reduction

30% – 45%

Lower overall costs

Easy and intuitive to use

The DDMRP in JD Edwards

Our solution is natively integrated with JD Edwards and does not require any interfaces.

It allows you to quickly integrate DDMRP logic into your environment, with a reduced IT effort, in a logic of deployment per site.

Figure 1 – Article Profile

Figure 2 – Planning Priorities

Figure 3 – Stock Projection

Figure 4 – Buffer History